Read More......

Muzica,boxe,sisteme,scheme,audio,sisteme home cinema,sony,mini sisteme,muzicale,wati,watt,putere,sunet,super boxe,amplificatoare,sisteme 5.1,2.1,acustica,incinte

Wzmacniacz mocy 2x0,5kW

Firma Tripath zajmująca się wzmacniaczami klasy D opracowała własną technologię obróbki sygnału Digital Power Processing (DPPTM) i wypuściła na rynek układy sterujące pozwalające na budowę wzmacniaczy w nowej klasie T (nazwa klasy T pochodzi najprawdopodobniej od nazwy firmy).

Wzmacniacze klasy T łączą w sobie jakość dźwięku uzyskiwaną w klasie AB z wysoką sprawnością uzyskiwaną w klasie D.

Układ TA0104A jest takim właśnie układem sterującym, który umożliwia zbudowanie wzmacniacza klasy T. Zasada działania wzmacniaczy klasy T jest podobna do wzmacniaczy impulsowych, czyli sygnał wyjściowy jest ciągiem impulsów o modulowanym wypełnieniu, z tą różnicą, że zmianie ulega również częstotliwość nośna. Częstotliwość nośna podlega zmianie w zależności od wielkości sygnału. Według danych katalogowych firmy Tripath, dla małych sygnałów częstotliwość ta wynosi ok. 1,5MHz i spada przy dużych sygnałach do 200kHz. Uzależnienie częstotliwości nośnej od wielkości sygnału powoduje, że wzmacniacze klasy T nie zniekształcają tak sygnału jak to ma miejsce w klasie D i ich pasmo jest porównywalne z pasmem wzmacniaczy klasy A lub AB.

Schemat ideowy wzmacniacza przedstawiony jest na rys.1. Sercem całego układu jest oczywiście układ U1. Sygnały wejściowe IN1 i IN2 (złącze J4) są doprowadzone poprzez filtry wejściowe do wejść IN1 i IN2 układu U1.

Rezystory R23 i R24 (RIN) ustalają wzmocnienie odpowiednio dla obu kanałów. Konstruktorzy z Tripath zalecają ustawić wzmocnienie na wartość 14,5 (23dB) co zapewnione jest przy wartościach rezystorów równych 49,9kW. Wzór, który przedstawia wzajemną zależność wzmocnienia Av i RIN wygląda następująco

Av=800·103/(RIN+5000)

gdzie RIN podaje się w Ohmach.

Kondensatory sprzęgające C22 i C23 (CIN) oddzielają składową stałą i wspólnie z rezystorami R23 i R24 ustalają dolną częstotliwość graniczną Fp (przy -3dB) dla sygnału wejściowego. Wzór, który przedstawia zależność Fp, CIN oraz RIN wygląda następująco

Fp=1/((2p·CIN)·(RIN+5000))

gdzie RIN podaje się w Ohmach, a CIN w faradach.

Do wejść IN1 i IN2 dołączony jest układ, w którym potencjometrami R18 i R22 ustala się napięcie na wejściach na wartość ok. 2,5V.

Układ TA0104A wyposażony jest również w system autodiagnostyki. O stanie układu informuje dioda LED D5, która jest sterowana z wyjścia HMUTE. Jeżeli dioda się świeci to oznacza właściwą pracę, gdy gaśnie to są niewłaściwe warunki pracy układu np. przeciążenie wyjścia lub przekroczenie wartości napięcia zasilania (zarówno od dołu jak i od góry).

W przypadku przeciążenia stopni wyjściowych ponowne załączenie wzmacniacza wymaga zmiany stanu wejścia MUTE w cyklu 0-1-0 lub wyłączenia i ponownego załączenia zasilania. W przypadku przekroczenia napięć zasilających wzmacniacz nie będzie pracował aż napięcia zasilające będą ponownie o właściwych wartościach.

Wejście MUTE służy do wyciszania wzmacniacza. Jeżeli na to wejście zostanie podany sygnał logicznej jedynki to wzmacniacz zostanie wyciszony, w chwilę po podaniu (200ms) na wejście sygnału o poziomie logicznego zera wzmacniacz będzie znowu w stanie normalnej pracy. Aby wzmacniacz był aktywny stale wystarczy zewrzeć styki 2-3 złącza J3.

Stopnie wyjściowe zbudowane są z par tranzystorów Q1,Q2 i Q3,Q4.

Tranzystory te dobiera się biorąc pod uwagę rezystancję dren-źródło w stanie włączenia RDS(ON), napięcie przebicia dren-źródło BVdss oraz ładunek gromadzony w bramce Qg. Najlepiej by było aby Qg i RDS(ON) były jak najmniejsze, gdyż ma to wpływ na szybkość przełączania i straty mocy. Są to jednak dwa sprzeczne warunki gdyż dla małej rezystancji RDS(ON) towarzyszy duży ładunek Qg. Poniżej znajduje się tabelka zawierająca dane tranzystorów, które były używane przez konstruktorów firmy Tripath do współpracy z TA0104A.

| Tranzystor | BVdss (V) | Qg (nC) | RDS(ON)(Ohm) |

|---|---|---|---|

| STW34NB20 | 200 | 80 | 0.075 |

| STW38NB20 | 200 | 95 | 0.065 |

| STW19NB20 | 200 | 40 | 0.18 |

Przy wyborze rezystorów zabezpieczających bramki tranzystorów (R1,R2,R9,R10) bierze się pod uwagę parametr Qg, który w połączeniu z tymi rezystorami ma wpływ na przełączanie tranzystorów. Tripath zaleca dla tranzystorów z Qg mniejszym niż 70nC stosowanie rezystorów o wartości 10W, a dla Qg większego niż 70nC stosowanie rezystorów o wartości 5,6W. Tranzystory wyjściowe są sterowane z układu procesora wbudowanego w układ TA0104A. Aby zoptymalizować jego pracę pod kątem szybkości przełączania tranzystorów należy skonfigurować go zworkami na złączach J1 i J2. Podczas przełączania par tranzystorów Q1, Q2 i Q3, Q4 procesor między cyklami włączania tranzystorów wstawia tzw. czas martwy (Break-Before-Make) kiedy to obydwa tranzystory powinny być wyłączone, co powinno zminimalizować straty energii, szczególnie przy wolniejszych tranzystorach. Prezentowany wzmacniacz ustawiony jest na 65ns. Poniżej znajduje się tabelka z konfiguracją zworek w zależności od czasu.

| Zwarte styki J1 | Zwarte styki J2 | Czas martwy (ns) |

|---|---|---|

| 1-2 | 1-2 | 145 |

| 1-2 | 2-3 | 105 |

| 2-3 | 1-2 | 65 |

| 2-3 | 2-3 | 25 |

| Nazwa elementu | Symbol | Ilość |

|---|---|---|

| 1µF 50V | C22,C23 | 2 |

| 10µF 100V | C29 | 1 |

| 82µF 25V | C28 | 1 |

| 100µF 150V | C3,C11,C16,C17 | 4 |

| 47pF 500V | C5,C9 | 2 |

| 10nF 50V | C24,C25,C26,C27 C33,C34,C35,C36 C37,C38 | 4 |

| 100nF 100V | C1,C2,C6,C7,C8 C12,C13,C14,C15 C18,C19,C20,C21 | 13 |

| 220nF 100V | C4,C10 | 2 |

| 0,01R 1W | R3,R8,R11,R12 | 4 |

| 5,6R 1W | R1,R2,R9,R10 | 4 |

| 33R 2W | R5,R6 | 2 |

| 1k 1W | R4,R7 | 2 |

| 2k 0,25W | R15 | 1 |

| 10k 0,25W | R13,R14,R16 | 3 |

| 49,9k 0,25W | R23,R24 | 2 |

| 1M 0,25W | R17,R19,R20,R21 | 4 |

| Pot. 10k 0,25W | R18,R22 | 2 |

| MUR120 | D1,D2,D3,D4 | 4 |

| MBR150 | D6 | 1 |

| LED zielona | D5 | 1 |

| 11,3µH 10A | L1,L2 | 2 |

| 1µH | L3,L4 | 2 |

| 1µH 10a | L6,L7 | 2 |

| 330µH | L5 | 1 |

| STW38NB20 | Q1,Q2,Q3,Q4 | 4 |

| TA0104A | U1 | 1 |

| LM2594HVN-12 | U2 | 1 |

| Listwa 1X3 | J1,J2,J3 | 3 |

| Złącze ARK2 | J4 | 2 |

| Złącze ARK3 | J5 | 2 |

| Układ zabezpieczenia głośników | ||

| 20k 0,25W | R26 | 1 |

| 100k 0,25W | R28,R30 | 2 |

| 220k 0,25W | R25 | 1 |

| 1M 0,25W | R27,R29 | 2 |

| 1µF 50V | C30,C31,C32 | 3 |

| MBR150 | D7 | 1 |

| BAT83 | D8 | 1 |

| 1N4148 | D9 | 1 |

| BS170 | Q5,Q6,Q7,Q9 | 4 |

| BC557 | Q8 | 1 |

| Złącze ARK2 | J6 | 2 |

| This design is a single fold transmission line using a 330mm (12") Audax driver (HD 33 S 66). The port loads out the back. Very little stuffing is used.

The stuffing could have be better optimised, reducing the effect of the null at 140 Hz. Since originally putting this project together more stuffing has been added making this a true TL. The preliminary results are that the stuffing improves the performance of the speaker. (details as they become available/ed) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

I have always been interested in horn loudspeaker designs, indeed one of my earliest constructional projects was a Gately superhorn powered by an 8 Watt valve amplifier (Push Pull 6BM8's) circa 1956.

At that time however there was very little information on the matching of drive units to horns with the result that the sonic result was less than optimum.

Recently my interest in horns was rekindled by articles on mid-range bass horns in Speaker Builder by Dr Bruce Edgar [1], so I decided to "Have a Go".

Most of the bass horn designs available were too large to be domestically acceptable. However I remembered a mini horn design by J. Dinsdale, in a series of articles on horn design in Wireless World during 1974 [2]. It had a cut off frequency of 70Hz, had a Tractix contour and used a 6 Inch (15 cm) drive unit. The rear of the cone driving the bass horn, and the front loaded with a mid-range horn.

It should be noted that this is a 1/8 scale horn designed to be placed in the corners of a room however as my realisation of this design fires downward and exhausts at the front and both sides at floor level, I reasoned it would also give a satisfactory bass performance when placed along a rear wall away from the corners. This later proved to be correct.

The next problem was to find a suitable drive unit for the two way loaded horn. The requirement was for a 6 to 7 Inch unit with fs approximately 50Hz, QES preferably less than 0.2 and high efficiency. Zalytron were advertising a Focal 7V513 unit which seemed to have possibilities - fs 46 Hz, QES 0.25, SPL 93 dB. I therefore obtained a pair of these units, however as these are not full range units a separate tweeter was required.

I chose a Focal T120 Ti02 foam surround unit. This unit has a SPL of 94 dB so I decided to also load this unit with a Tractrix horn to better match the efficiency of the bass/mid range. Additional magnets were also added this did not increase efficiency as expected, but improved the decay characteristics as demonstrated by waterfall plots taken with an IMP measuring system.

The mid-range horn has a Tractrix contour with a 300 Hz cut off frequency as used in the Edgar mid range horn, it has a square mouth and a circular throat the square mouth was used in preference to Dr Edgar's 2/1 ratio to minimise cabinet width. The horn is solid chipboard, laminated from 11 pieces, 12 mm thick.

Testing of the mid-range horn with the Focal 7V513 indicated that efficiency fell off above 2 kHz. A rather low 2kHz crossover was therefore required for the tweeter (12 dB/Octave Linkwitz Reilly).

The efficiency of the complete system has not been measured but I estimate it to be between 95dB and 97dB/W/Meter.

It is a fact of life that nothing stays the same very long with a DIY project, there is always another tweak to be tried - So read on

Just when I was getting used to the wonderful, natural sound of these horn speakers, along with came an article from Sound Practices [3] giving a history of Lowther loudspeakers - Those world renowned UK manufactured full range units, much sought after for horn loudspeakers. I was intrigued by the simple treble (whizzer) cone and pear shaped phase plug used to horn load the treble cone and I wondered how my 7 Inch Focal units would sound with the treble cone setup.

I used a thin cartridge paper to make a 73 mm diameter cone with a 73 degree included angle. This was attached to the main cone with a multi bond adhesive taking great care not to run adhesive into the voice coil gap.

As the Focal unit already uses a phase plug I fitted a larger pear shaped phase plug (turned from pine timber) over the existing one.

This modification worked very well. The frequency response now extended out to 14/15 kHz but the upper mid-range / treble level was somewhat low.

A notch filter was then introduced centred on 1 kHz to reduce the peak between 500 Hz and 1500 Hz. The formula for the filter were obtained from Vance Dickersons Loudspeaker cookbook.

The system now sounded much better balanced although a few dB's of efficiency were lost in the process. The tweeter is now only required above 15 kHz and is rolled off using a 6dB / Octave filter.

The system now sounds great, it has all those wonderful attributes you expect from horn loudspeakers.

I may later try different drive units - perhaps Fostex FE168E but for the moment I am content. I have included drawings and sketches to show the construction of the horns. Although I built them in two sections to make them easier to transport, they could be built as single units.

The horns were finished with an iron on, real wood veneer (Queensland Walnut) sealed with a flat urethane and finished with Danish oil.

The amplification used is home built - a Nelson Pass 20 Watt single ended class A solid state power amplifier and a Mu follower valve line level pre-amplifier built from a local kit (Contan Audio). I used a high quality components Holco resistors, Solen and MIT caps and solid silver wiring - They sound great.

At the moment the system only has a CD front end, using a Rotel RCD965BX player, but I am building a valve phono pre-amplifier - the first stage of the four valve pre-amplifier from Alan Wright's pre-amplifier cookbook built on copper ground planes plated gold over silver.

I hope the above will inspire some of you DIYers out there to "Have a Go", the rewards are well worth the effort.

DIY forever

Alf Lepp

Click on the drawings to get a (much) larger picture

W. Marshall Leach, Jr., Professor

Georgia Institute of Technology

School of Electrical and Computer Engineering

Atlanta, GA 30332-0250

In the spring of 1999, mechanical engineering student Chris Germann asked me if he could receive special problem credit for the design and construction of a loudspeaker system. I approved his project and agreed to be his advisor. The system that Chris designed is described on this page. It is a three way system with a dual voice coil woofer in a center channel enclosure and two satellite speakers.

In the spring of 1999, mechanical engineering student Chris Germann asked me if he could receive special problem credit for the design and construction of a loudspeaker system. I approved his project and agreed to be his advisor. The system that Chris designed is described on this page. It is a three way system with a dual voice coil woofer in a center channel enclosure and two satellite speakers.

You can see a picture of Chris's system here.

You can see a picture of Chris's system here.

The woofer that we chose is the MCM 55-1465 12-inch dual voice coil woofer. It is available from MCM Electronics. This is a very high quality driver for the price. With the two voice coils connected in parallel, the small-signal parameters that we measured are as follows:

The woofer that we chose is the MCM 55-1465 12-inch dual voice coil woofer. It is available from MCM Electronics. This is a very high quality driver for the price. With the two voice coils connected in parallel, the small-signal parameters that we measured are as follows:

We decided to use a vented-box enclosure for the woofer. For its design, we assumed the box quality factor QL = 7. From the QL = 7 design chart, the vented-box design data for QTS = 0.326 is as follows:

We decided to use a vented-box enclosure for the woofer. For its design, we assumed the box quality factor QL = 7. From the QL = 7 design chart, the vented-box design data for QTS = 0.326 is as follows:

With the above data, the woofer enclosure parameters can be calculated as follows:

With the above data, the woofer enclosure parameters can be calculated as follows:

In the calculations, we neglected the effect of the resistance of the inductors in the crossover network on the woofer parameters. This resistance has the effect of increasing the effective quality factor of the woofer, which would require a bigger box. One of the criteria that we decided on at the start was a woofer box volume not greater than about 2 cubic feet. A higher quality factor would result in a bigger box, which we did not want. With the box design described here, the effect of the crossover network resistance is to cause a slight peak lift in the lowest bass frequencies, an effect that we considered desirable.

In the calculations, we neglected the effect of the resistance of the inductors in the crossover network on the woofer parameters. This resistance has the effect of increasing the effective quality factor of the woofer, which would require a bigger box. One of the criteria that we decided on at the start was a woofer box volume not greater than about 2 cubic feet. A higher quality factor would result in a bigger box, which we did not want. With the box design described here, the effect of the crossover network resistance is to cause a slight peak lift in the lowest bass frequencies, an effect that we considered desirable.

For the vent, we chose a tube with a 3-inch internal diameter. For a Helmholtz frequency of 34 Hz, the vent length calculates to be 5-1/2 inches long.

For the vent, we chose a tube with a 3-inch internal diameter. For a Helmholtz frequency of 34 Hz, the vent length calculates to be 5-1/2 inches long.

The drivers that we chose for the midrange and the tweeter are as follows:

The drivers that we chose for the midrange and the tweeter are as follows:

Both of these are very high quality drivers. The midrange is one of the best that I have tested, especially when it is put into a closed box enclosure that is large enough to obtain a low resonance frequency. Two each of these drivers are required for the system.

Both of these are very high quality drivers. The midrange is one of the best that I have tested, especially when it is put into a closed box enclosure that is large enough to obtain a low resonance frequency. Two each of these drivers are required for the system.

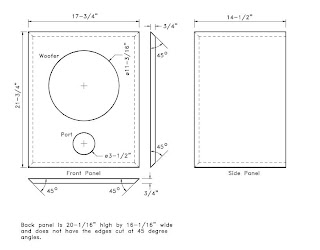

The box designs assume a wall thickness of 3/4". The woofer enclosure is braced internally with 1-1/2" by 1-1/2" bracing. Cabinet makers often will tell you that they can make boxes that are just as sturdy without the bracing, but don't believe it. The sattelite enclosures have 3/4" by 3/4" bracing around the back only. The bracing for all three boxes is recessed from the back by 3/4" + 1/16" = 13/16". The extra 1/16" is for the thickness of the foam tape around the back bracing that is used for an air-tight seal when the back panel is screwed to the bracing. The enclosures and internal bracings are described in the following figures:

The box designs assume a wall thickness of 3/4". The woofer enclosure is braced internally with 1-1/2" by 1-1/2" bracing. Cabinet makers often will tell you that they can make boxes that are just as sturdy without the bracing, but don't believe it. The sattelite enclosures have 3/4" by 3/4" bracing around the back only. The bracing for all three boxes is recessed from the back by 3/4" + 1/16" = 13/16". The extra 1/16" is for the thickness of the foam tape around the back bracing that is used for an air-tight seal when the back panel is screwed to the bracing. The enclosures and internal bracings are described in the following figures:

To minimize splintering around the edges when the final panel cuts are made, use a utility knife and a straight edge to make the first cut into the wood. Then use the saw to make the final cut. The hole diameters labeled on the figures for the drivers and the port are from Chris's report. These should be checked to be sure they are correct before cutting the holes.

The woofer enclosure dimensions account for the internal volume occupied by the driver, the bracing, and the vent tube. The ratios of its internal dimensions are 0.8 by 1.0 by 1.25. These are one of the two optimum ratios for a woofer enclosure. (The others are 0.6 by 1.0 by 1.6.) The enclosure should be lined with 1-inch thick fiberglass. Do not cover the back of the woofer or the port tube with fiberglass. The sattelite enclosures should be filled with fiberglass. It should not be compressed. You can purchase the fiberglass from Radio Shack. It should not take more than 2 bags for the 3 enclosures.

The woofer enclosure dimensions account for the internal volume occupied by the driver, the bracing, and the vent tube. The ratios of its internal dimensions are 0.8 by 1.0 by 1.25. These are one of the two optimum ratios for a woofer enclosure. (The others are 0.6 by 1.0 by 1.6.) The enclosure should be lined with 1-inch thick fiberglass. Do not cover the back of the woofer or the port tube with fiberglass. The sattelite enclosures should be filled with fiberglass. It should not be compressed. You can purchase the fiberglass from Radio Shack. It should not take more than 2 bags for the 3 enclosures.

I recommend building the enclosures with 3/4" veneered plywood. After the panels are cut, they can be nailed together on the outside with thin finishing nails. Corner clamps are useful to hold the panels together at a 90 degree angle when nailing them together. The nails should be counter sinked and the holes filled with wood filler. The internal bracing is screwed from the inside of the boxes. Holes for the screws should be drilled in the bracing first. Then apply glue to the bracing and screw it to the insides of the box with wood screws or dry-wall screws. (I prefer the latter.) C clamps should be used to hold the bracing to the box while putting the screws in. It is best not to remove the C clamps until the glue has set up. The specified length of each bracing piece has been reduced by 1/16" to make sure it will fit the box without being forced. Any gaps can be filled with caulk after the the glue has set up.

I recommend building the enclosures with 3/4" veneered plywood. After the panels are cut, they can be nailed together on the outside with thin finishing nails. Corner clamps are useful to hold the panels together at a 90 degree angle when nailing them together. The nails should be counter sinked and the holes filled with wood filler. The internal bracing is screwed from the inside of the boxes. Holes for the screws should be drilled in the bracing first. Then apply glue to the bracing and screw it to the insides of the box with wood screws or dry-wall screws. (I prefer the latter.) C clamps should be used to hold the bracing to the box while putting the screws in. It is best not to remove the C clamps until the glue has set up. The specified length of each bracing piece has been reduced by 1/16" to make sure it will fit the box without being forced. Any gaps can be filled with caulk after the the glue has set up.

After the glue has set up, the inside joints can be sealed with glue or caulk to prevent any possible air leaks. I prefer clear silicon rubber caulk (not the paintable kind). Caulk should also be applied around the vent tube inside the box. The drivers can be screwed to the front panel with wood screws or dry-wall screws. Because dry-wall screws have a black color, I prefer them. Do not mount the drivers from the inside of the box.

After the glue has set up, the inside joints can be sealed with glue or caulk to prevent any possible air leaks. I prefer clear silicon rubber caulk (not the paintable kind). Caulk should also be applied around the vent tube inside the box. The drivers can be screwed to the front panel with wood screws or dry-wall screws. Because dry-wall screws have a black color, I prefer them. Do not mount the drivers from the inside of the box.

You can see the circuit diagram for the crossover network for one channel here.

You can see the circuit diagram for the crossover network for one channel here.

Note that the midrange and tweeter are both connected with reversed polarity to the crossover network. This is necessary to prevent phase cancellation between the woofer and the midrange at the crossover frequency. The resistors in the midrange and tweeter networks form L-pad attenuators to equalize the on-axis pressure sensitivities of the drivers. Without these resistors, the highs would be much too bright. I recommend using printed circuit boards for the crossover networks. Most of the suppliers of loudspeaker drivers sell these. You may not find holes on the printed circuit boards for the L-pad resistors in the midrange and tweeter networks, but they can be easily added. Do not use any pre-made crossover networks.

Note that the midrange and tweeter are both connected with reversed polarity to the crossover network. This is necessary to prevent phase cancellation between the woofer and the midrange at the crossover frequency. The resistors in the midrange and tweeter networks form L-pad attenuators to equalize the on-axis pressure sensitivities of the drivers. Without these resistors, the highs would be much too bright. I recommend using printed circuit boards for the crossover networks. Most of the suppliers of loudspeaker drivers sell these. You may not find holes on the printed circuit boards for the L-pad resistors in the midrange and tweeter networks, but they can be easily added. Do not use any pre-made crossover networks.

To provide access to the inside of the boxes, the rear panels are not glued in place. For an air tight seal, put closed-cell foam weather stripping (sometimes called camper tape) around the bracing that the rear panels are screwed to. I recommend the 3/16" thick by 1-1/4" wide self-adhesive, closed-cell vinyl foam weatherstrip tape made by Macklanburg Duncan Co., Dennis, or ACE Hardware. (The ACE part number is 85017.) When the screws for the rear panel are installed, they should be tightened just enough to compress the weather-stripping by about 1/8" so that the rear panel will fit flush.

To provide access to the inside of the boxes, the rear panels are not glued in place. For an air tight seal, put closed-cell foam weather stripping (sometimes called camper tape) around the bracing that the rear panels are screwed to. I recommend the 3/16" thick by 1-1/4" wide self-adhesive, closed-cell vinyl foam weatherstrip tape made by Macklanburg Duncan Co., Dennis, or ACE Hardware. (The ACE part number is 85017.) When the screws for the rear panel are installed, they should be tightened just enough to compress the weather-stripping by about 1/8" so that the rear panel will fit flush.

Here are some links to suppliers of loudspeaker components:

Here are some links to suppliers of loudspeaker components:

A wood working shop that built speakers for two students in the Spring 2000 semester is Atlanta Wood Trends, 404-696-7434. The man who runs the shop is Scott LaPointe. The man who did the job is named Jim. The cost for was $125 for two satellite boxes and one woofer box made of birch veneered plywood. If you have them make boxes for you, be sure to tell the worker that you want the bracing and that you want it cut from solid wood, not plywood. Also, have a written and signed contract before you make the down payment. When the students went to pick up their boxes, there seemed to be a misunderstanding over exactly what the deliverables were. A signed contract could have prevented this.

This page is not a publication of the Georgia Institute of Technology and the Georgia Institute of Technology has not edited or examined the content. The author of this page is solely responsible for the content. Copyright 1999. All rights reserved.

This page is not a publication of the Georgia Institute of Technology and the Georgia Institute of Technology has not edited or examined the content. The author of this page is solely responsible for the content. Copyright 1999. All rights reserved.

| The CaseThe case is as important as the drivers to make a good speaker! An ideal case does not vibrate at all - the driver's membranes are the only thing that should move. To get a "dead" case I built the case from 18 mm particle-board (inside) and 10 mm MDF (outside). I put ceramic tiles on the inside (like tiles in your bathroom), then a layer of "Hawaphon" (lead particles). On top of all this I put 10 mm felt and some wool to damp resonances/reflections inside the case. All in all the thickness of the walls is about 4 cm (without the felt).The I used a bass-reflex construction to get enough bass-SPL: I put two channels in the bottom of the case, "looking" to the floor (the speaker stands on spikes, about 2 cm above the floor). The idea of this arrangement is that the midrange "garbage" coming out of the bass-reflex channels is damped by the carpet. The internal volume of the case is about 18 Liters. The front is 18.8 cm wide which is about the diameter of the woofer. It is important to make the front as narrow as possible to move the frequencies where reflections from the corners of the case appear as high as possible (away from the frequency-range whrere the ear is most sensitive). Maybe I'll build a new case some day. I might change the following:

|

| L1 = 1.8 mH L2 = 15 mH C1 = 10 µF C2 = 15 µF C3 = 3.9 µF R1 = 5.6 Ohm R2 = 4.4 Ohm (tot. resistance of LCR including L2) R3 = 1 Ohm |

| C4 = 3.9 µF L3 = 0.82 mH R5 = 10 Ohm R6 = 8.9 Ohm |